For use on Exotic Hardwoods, Thermally Modified Softwoods, & Composite Decking

ExtremeS® Deck Fastener System has many advantages. Not only does this all-weather deck fastening system help build stronger decks, your customers will also save money in both initial installation costs and long-term maintenance thanks to:

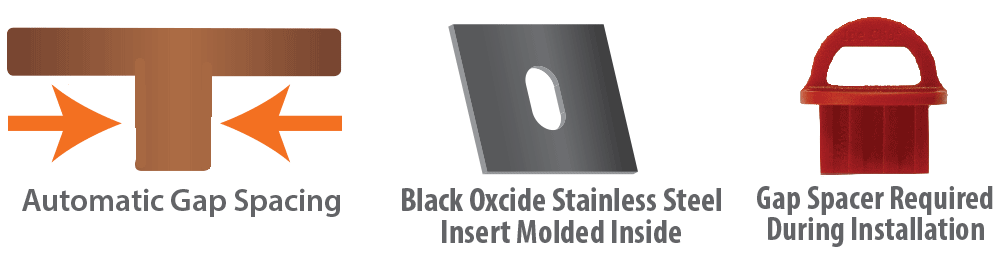

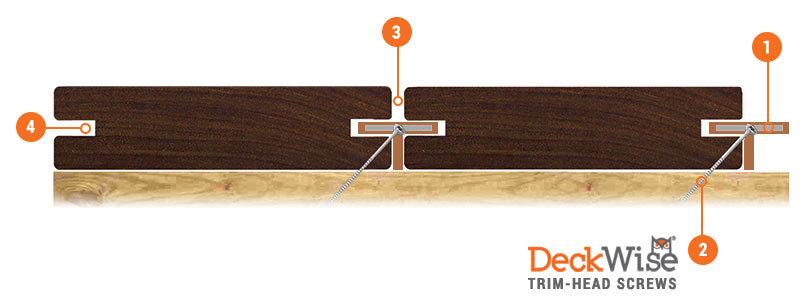

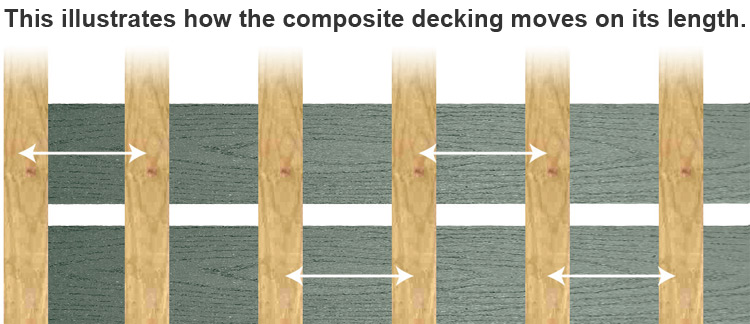

With a square shape and stainless steel insert, the ExtremeS® fits both pre-routed grooves and pregrooved decking. With 5/32” [4 mm] spacing between the boards, the ExtremeS® fastener allows hardwood boards expand and contract without pushing into each other. Also, by allowing composite decking & PVC decking to expand on its length the ExtremeS® extends the lifespan of these popular materials.

Do It Once, Do It Right, Do It Out Of Sight!™

EXTREME® Ipe Clip® Series - U.S. Patent Numbers 8,464,488 and 8,806,829. Original, “round”, STANDARD Ipe Clip® - U.S. Patent No. D470,039. EXTREMEKD® and EXTREME4® Licensed under U.S. Patent Nos. 7,874,113 and 8,161,702 Patent.

Strength: Ipe Clip® fasteners are manufactured from a UV Resistant High Strength material, giving Ipe Clip® fasteners up to three times the strength of other fastening methods. By using our high strength material, Ipe Clip® fasteners have increased holding power, and help prevent screw heads from being overdriven, as can be a problem with other lesser quality fasteners.

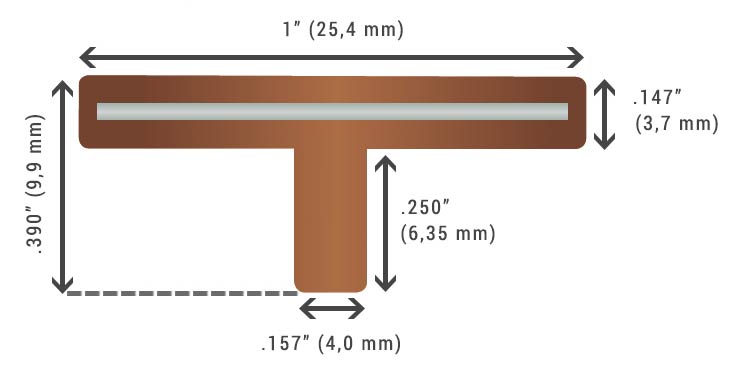

Shape: Due to its size and shape, Ipe Clip® fasteners speed installation and eases installation problems associated with other hidden fastener methods. The smaller shape allows for approx. 1” of tolerance in the positioning of the slots cut by a biscuit jointer. Other hidden fastener methods do not allow for any tolerance in the cutting of the biscuit slots, which complicates and slows installation.

Insert: All of our ExtremeS® hidden deck fasteners are manufactured with a hardened stainless steel, black oxide coated insert inside a UV and chemical-resistant polyethylene outer shell.

Legs: The Ipe Clip® ExtremeS® has been engineered with a highly versatile leg that allows it to be compatible with nearly all decking materials.

Leg height = .242" [6,14 mm]Ipe Clip® complete kits are available in 100 & 175 count boxes, as well as our Contractor Buckets

| Material | Stainless Steel Insert | Available Colors |

| Polyethylene | .883" x .883" Thickness: .036" |

|

| Air Dried | Kiln Dried | PVC/Composite |

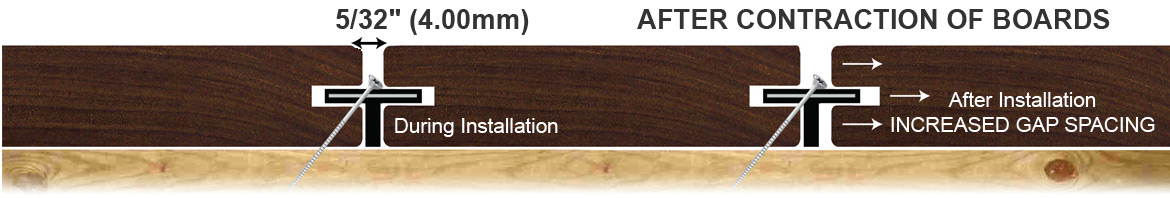

The method of 45 degree screws hold the decking tight to the joist, while allowing one side of the deck board to remain free to contract.

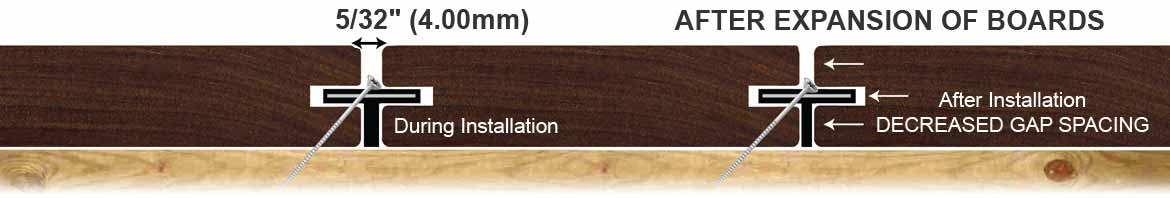

The method of 45 degree screws hold the decking tight to the joist, while allowing one side of the deck board to remain free to expand.

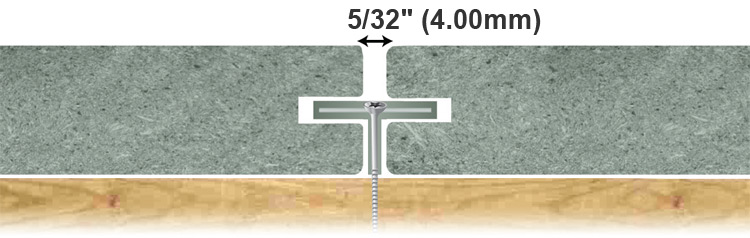

Running screws straight down with composite/PVC decking allows these materials to naturally move on their length.

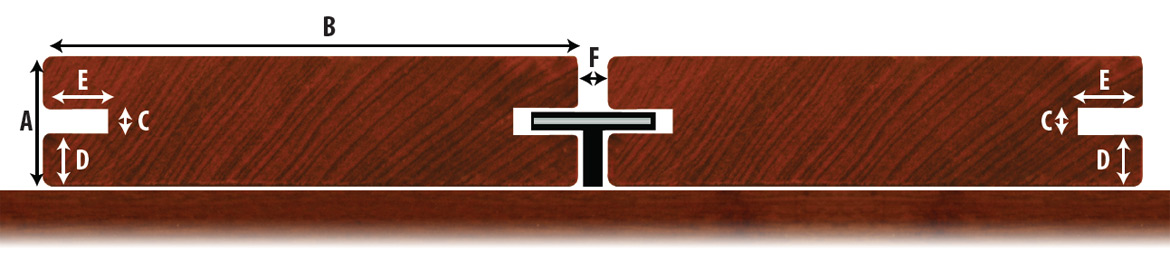

| Board Thickness | Board Width |

| A* = Your Measurement | B** = Your Measurement |

| Thickness of Cut | Cutting Height | Cutting Depth |

| C = 5/32"(4mm) | D*** = (A-5/32")/2 | E = 1/2"(13mm) |

| During Installation |

| F**** = 5/32" (4mm) |

If using 1-1/2" or thicker material, you may need to upgrade to a longer screw option than what is typically packaged with the fastening kit.

** For decking 8" or wider, the (A) dimension should be at least 1-1/2". Using a wide plank such as this for surface decking will most likely cause cupping issues regardless of how the material is fastened if thicker material is not used.

*** This formula will create a symmetrical profile that allows you to flip and/or rotate the decking to be able to put the best side up.

**** Fastener automatically achieves correct gap spacing when boards are pushed tight during installation.