Economical solution ideal for Air-Dried Hardwoods, Composite Decking, & PVC Decking

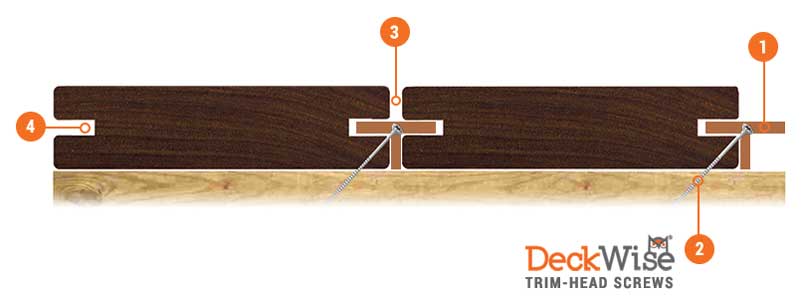

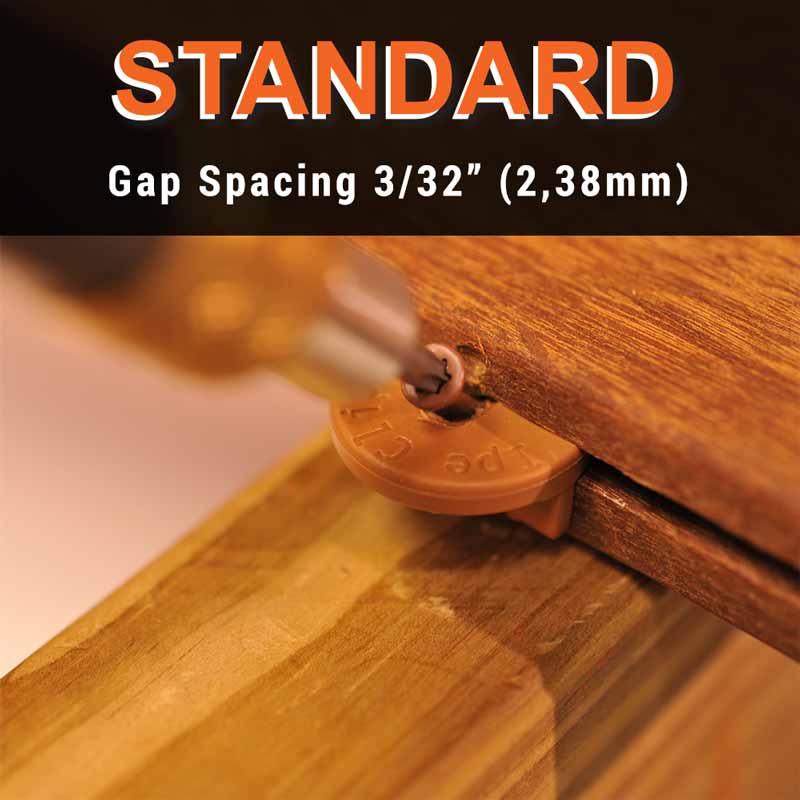

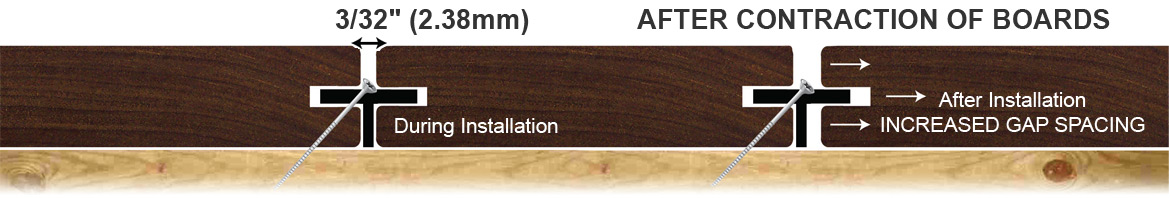

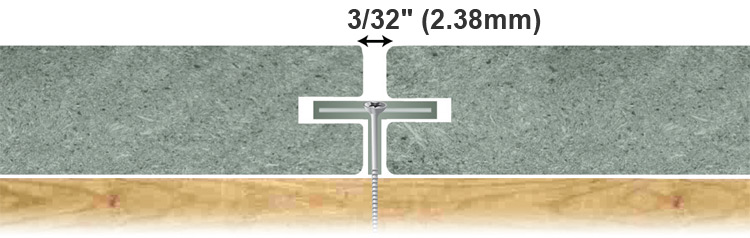

The Ipe Clip® Standard Hidden Deck Fastener System features a Quick & Easy installation process because all the work is done from the top-side of the deck so there is no need to stand on your head during the installation of the deck. The installation process is made even more simple because Ipe Clip® Standard Hidden Deck Fasteners automatically set a 3/32" [2,38mm] gap spacing between the installed deck boards. No gap space measuring is needed when you choose Ipe Clip® Hidden Deck Fastening systems.

Do It Once, Do It Right, Do It Out Of Sight!™

The reason Ipe Clip® Standard Hidden Deck Fasteners set a smaller gap between deck boards than Ipe Clip® ExtremeKD® Hidden Deck Fasteners is because different decking materials require different gap spacing. For example air dried decking material will tend to contract on its width more than kiln dried material so a smaller gap space between boards is required. Ipe Clip® Standard Hidden Deck Fasteners are installed with one side of the decking board free to contract and expand on its width as needed.

EXTREME® Ipe Clip® Series - U.S. Patent Numbers 8,464,488 and 8,806,829. Original, “round”, STANDARD Ipe Clip® - U.S. Patent No. D470,039. EXTREMEKD® and EXTREME4® Licensed under U.S. Patent Nos. 7,874,113 and 8,161,702 Patent.

Strength: Ipe Clip® fasteners are manufactured from a UV Resistant High Strength material, giving Ipe Clip® fasteners up to three times the strength of other fastening methods. By using our high strength material, Ipe Clip® fasteners have increased holding power, and help prevent screw heads from being overdriven, as can be a problem with other lesser quality fasteners.

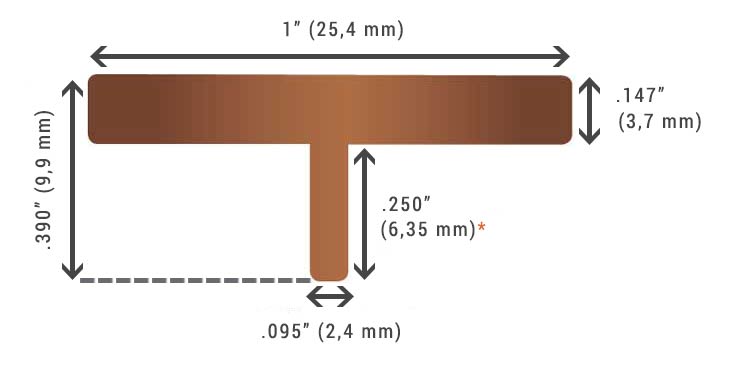

Shape: Due to its size and shape, Ipe Clip® fasteners speed installation and eases installation problems associated with other hidden fastener methods. The smaller shape allows for approx. 1” of tolerance in the positioning of the slots cut by a biscuit jointer. Other hidden fastener methods do not allow for any tolerance in the cutting of the biscuit slots, which complicates and slows installation.

Economical: Unlike our Extreme® line of fasteners, our Standard fastener does not include a stainless steel insert. Manufactured using fiberglass reinforced polyethylene, our standard fasteners are high strength and highly affordable!

Legs: The Ipe Clip® has a thin leg which helps maintain a perfect gap spacing when materials are expanding and contracting due to varying climate conditions.

Leg height = .242" [6,14 mm]Ipe Clip® complete kits are available in 100 & 175 count boxes, as well as our Contractor Buckets

| Material | Stainless Steel Insert | Available Colors |

| Polyethylene/ Fiberglass |

|

| Air Dried | Kiln Dried | PVC/Composite |

The method of 45 degree screws hold the decking tight to the joist, while allowing one side of the deck board to remain free to contract.

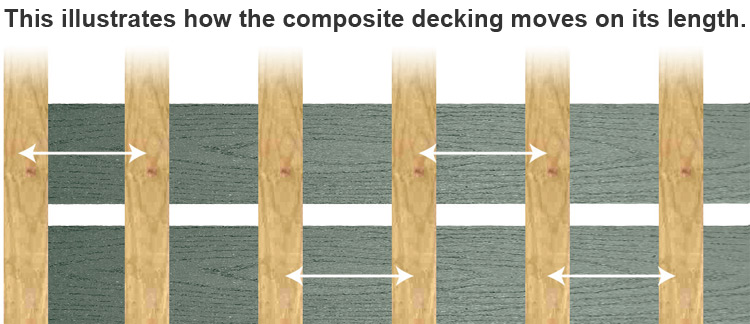

Running screws straight down with composite/PVC decking allows these materials to naturally move on their length.

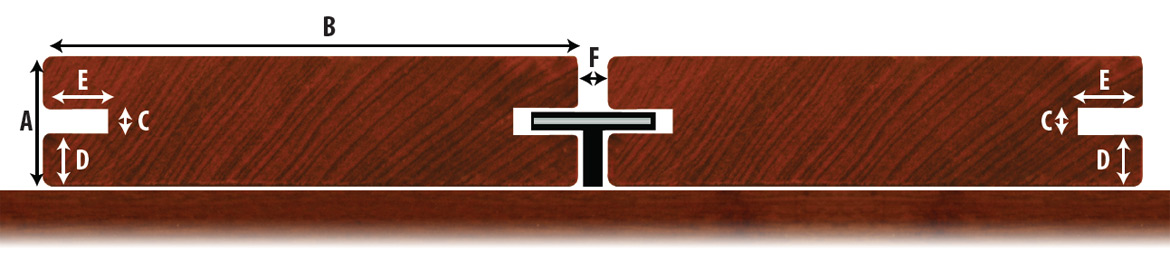

| Board Thickness | Board Width |

| A* = Your Measurement | B** = Your Measurement |

| Thickness of Cut | Cutting Height | Cutting Depth |

| C = 5/32"(4mm) | D*** = (A-5/32")/2 | E = 1/2"(13mm) |

| During Installation |

| F**** = 3/32" (2,38mm) |

If using 1-1/2" or thicker material, you may need to upgrade to a longer screw option than what is typically packaged with the fastening kit.

** For decking 8" or wider, the (A) dimension should be at least 1-1/2". Using a wide plank such as this for surface decking will most likely cause cupping issues regardless of how the material is fastened if thicker material is not used.

*** This formula will create a symmetrical profile that allows you to flip and/or rotate the decking to be able to put the best side up.

**** Fastener automatically achieves correct gap spacing when boards are pushed tight during installation.